Closed Head Pail – Tighthead

Non-removable top ideal for products that need a higher UN rating A variety of fittings available Has the highest UN rating available of any pail design and approved for air shipments Stackable design Strong galvanized steel handle Triplex® throughout the top and bottom seamsUN Drop Test

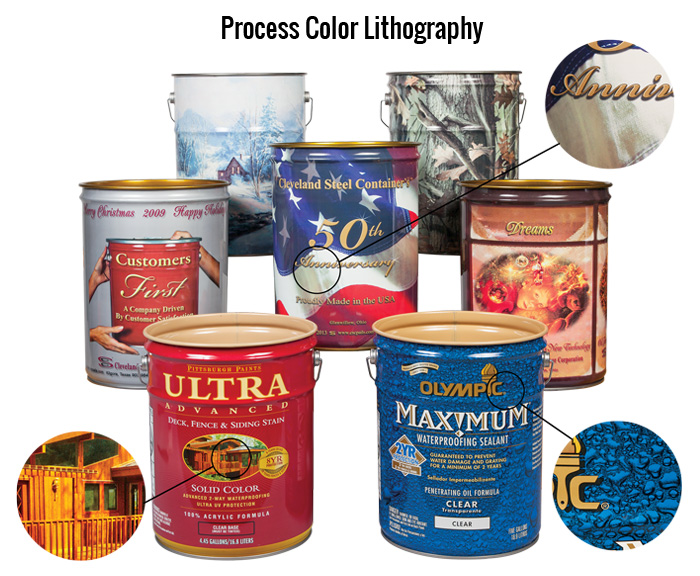

Metal Decoration (Lithography)

Interior Coating Selections

Standard Pail Sizes for Tighthead Pails (in gallons)

2.5 | 3 | 3.5 | 4 | 5 | 5.3 | 5.5 | 6 | 6.5 | 7

Pail sizes vary by height only, custom sizes available upon request

We offer a variety of different cover fitting options for dispensing or tinting your products including:

- Extendable pour spouts

- 2” and 3⁄4” drum fittings in both nylon and steel

- Tint and vent plugs

- Plastic and metal screw caps and dust caps

For a complete list of fitting options please contact us.

We offer several different interior coating options that are compatible with a wide variety of products. If requested , we can assist you in selecting the proper interior coating for your products. We strongly recommend that our customers conduct testing on the interior coating to determine final compatibility for your products.

RUST INHIBITOR

The purpose of a rust inhibitor is to slow down the formation of rust. It is not intended to act as a protective lining. With time and exposure conditions, the formation of rust may still occur. If rust concerns are an issue, then the use of a lined pail will prevent the formation of environmental rust. These inhibitors have limited chemical resistance to most products but are not as good as the epoxy-phenolics or straight 100% phenolic linings options.

EPOXY PHENOLIC

The advent of epoxy resin has improved the flexibility of the lining and has excellent resistance to alkaline products. In general, the epoxy-phenolic lining has been designed to provide outstanding chemical resistance for products that have a pH range of 7.0–9.0. Typical products packaged, are alkaline products, fatty acids, detergents, emulsions, foods, general organic chemicals, surfactants, and water based resins.

RED PHENOLIC

Red phenolic linings are unmodified phenolics and as such, have a high degree of acid and solvent resistance, and are not recommended for alkaline products. In general, they are designed for holding products that have a pH range of 3.0–7.0. A properly cured lining will exhibit good adhesion and limited flexibility. Typical products which do not affect the lining are acid compounds, agricultural chemicals, insecticides, corrosive chemicals, solvents and solvent containing materials, nitrocellulose lacquers and inks, food products, essential oils and petroleum products.

GREEN PHENOLIC

Green phenolic linings are unmodified phenolics and as such, have a high degree of acid and solvent resistance, and are not recommended for alkaline products. In general, they are designed for holding products that have a pH range of 3.0–7.0. A properly cured lining will exhibit good adhesion and limited flexibility. Typical products which do not affect the lining are acid compounds, agricultural chemicals, insecticides, corrosive chemicals, solvents and solvent containing materials, nitrocellulose lacquers and inks, food products, essential oils and petroleum products.

GOLD PHENOLIC

Gold phenolic linings are unmodified phenolics and as such, have a high degree of acid and solvent resistance, and are not recommended for alkaline products. In general, they are designed for holding products that have a pH range of 3.0–7.0. A properly cured lining will exhibit good adhesion, however; compared to the red and green phenolic lining it is less flexible. Typical products which do not affect the lining are acid compounds, agricultural chemicals, insecticides, corrosive chemicals, solvents and solvent containing materials, nitrocellulose lacquers and inks, food products, essential oils and petroleum products.

Standard Exterior Colors

Standard colors are white, gray and black

Premium Exterior Colors

Premium colors shown do not represent actual color or our entire color selection. Please contact us for a color chip for color matching.

Let us help you design your lithographed steel pail or cover and turn your steel pail into a cost effective marketing tool. We do all of our printing in-house using either conventional or UV ink with state of the art computer controlled ink applicators on our printing presses. To help maintain short and consistent lead-times, all of our pail manufacturing plants have their own metal decorating operations.

Spot Colors

Spot color designs can be cost effective when utilizing only a few solid colors. A lithographed pail or cover will allow you to proudly display your company name, logo or color. It also provides plenty of print area for product information, application instructions, hazardous and warning statements and other important information. A varnish overcoat is applied to protect your design.

Process Colors

Process color designs allow for photographic images to be printed with crystal clear detail. The images are created from process colors – cyan, magenta, yellow and black (CMYK). This type of lithography will feature your product’s full potential such as life- like water droplets, wood grain and fabric texture.

Inserts, Liners, and Specialty Products